Washdown environments in food and beverage processing

In food and beverage processing, pressure washing with hot water and caustic agents creates a variety of reliability problems. Lubricants can be washed out, resulting in a need for frequent relubrication. Corrosion can occur in areas with poor chemical resistance, creating flaking and possible contamination. These combined effects result in reduced bearing service life, as well as increased costs for relubrication.

But it does not have to be like that. Learn from our customers

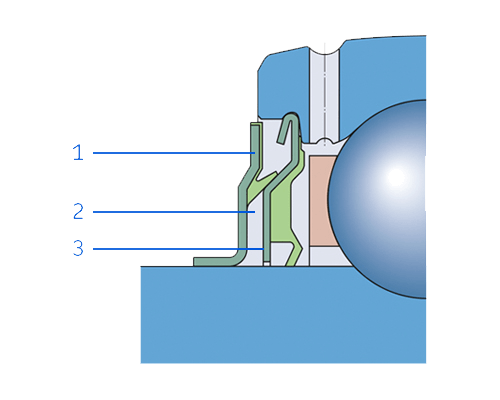

The 2RF bearing seal arrangement

SKF bearing seal technology

What if you could eliminate the need to relubricate bearings after each washdown?

The 2RF seal arrangement provides excellent protection against detergent penetrating into seal contact areas:

- The flinger adds mechanical and centrifugal protection against contaminants entering the bearing cavity, and provides a first contacting seal with its rubberized lip acting axially against the gasket seal.

- The space between the flinger rubberized lip and the gasket seal is filled with food grade grease in order to provide additional protection.

- Additional sealing efficiency is achieved through the labyrinths created by the flinger’s external diameter and the outer ring, plus the metallic seal insert and the inner ring shoulder.

By fitting SKF Food Line Y-bearing units that utilize bearing seal technology, you can:

Decrease costs of lubricant, labour

and bearing replacements

Reduce unplanned stops due

to ineffective relubrication

Support proactive food safety programs

Reduce use of water, lubricant and contamination of waste water

Improve operator safety

Read on: What our industry expert say and what benefits our customers achieved

"Companies have an opportunity to solve ongoing issues by applying relubrication-free bearing technology

that delivers significant cost savings, food safety and environmental improvements"

Read more

-

Stephen White, SKF Food & Beverage Industry Portfolio Manager

Benefits our customers achieved

A dairy plant saves 57,000 Euro per year, through reduced grease consumption, maintenance resources and water usage.

Get the full storyRead more about the available range and technical specifications

Equipped with the bearing seal technology, these bearing units withstand high pressure washdowns without the need to relubricate.

SKF Food Line Y- bearing units