Challenges in wet, humid and contaminating environments

Operating bearings in wet, humid and contaminating environments – and subjecting them to frequent washdowns increases the chances of moisture seeping into the bearing, emulsifying the grease and causing leakage. This can not only lead to bearing failures and downtime, but may also risk food contamination and operator safety if the grease leaks on to the floor.

But it does not have to be like that. Learn from our customers

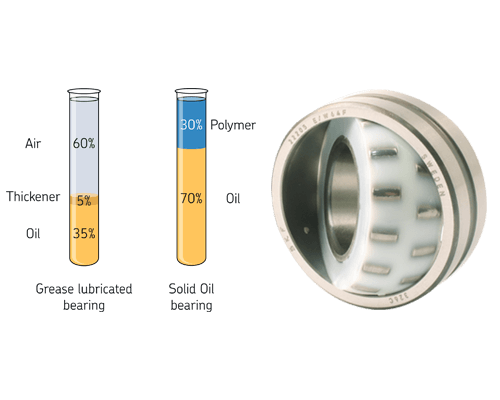

Solid Oil provides prolonged lubrication to the bearing

Solid Oil bearing lubrication technology

What if there was a way to avoid the typical issues while making sure the bearings used in high-humidity and contaminating applications are optimally suited to perform under such environmental conditions?

Featuring oil-saturated polymer matrix, SKF bearings with Solid Oil technology are relubrication-free and designed to withstand the negative effects brought on by high humidity levels or breathing in the bearings caused by rapid temperature shifts (for example in freezer applications). The Solid Oil matrix contains two to four times more oil than in conventional greased bearings, completely filling the internal space in the bearing, making relubrication unnecessary. Available as NSF H1 food approved variant.

By implementing Solid Oil bearing lubrication technology, you can:

Lower maintenance costs

Reduce planned and

unplanned downtime

Minimize risk of food contamination

from bearing grease

Reduce waste of grease and

clean-up disposal

Improve operator safety

Read on: What our industry expert say and what benefits our customers achieved

"SKF bearings with Solid Oil lubrication technology are yet another example of the emphasis SKF places

on helping companies reconsider and rethink their current relubrication practices"

Read more

-

Stephen White, SKF Food & Beverage Industry Portfolio Manager

Benefits our customers achieved

See how a bakery achieved 10 years with no unplanned downtime in bread proover, using SKF deep groove ball bearings with Solid Oil

Get the full storySolid Oil technology can be used in virtually all bearing types with sufficient internal free space.

Check the bearings below

*MRC is a brand of SKF